Skip To Content

Machinery List – .040 to 3 1/4 diameter capacities will hold .001 tolerance

Screw Machines

- 2 – 2 3/8 cap. Ultramatics

- 7 – 1 5/8 cap. Ultramatics

- 1 – 1 1/2 cap. Ultramatic

- 4 – 1 1/4 cap. Ultramatics

- 3 – 3/4 cap. Ultramatics

- 1 – 5/8 cap. 00 Ultramatics

- 10 – 1/2 cap. 00 Ultramatics

- 1 – 1 1/2 Hand screw

Multi Spindle Machines

- 1 – 3 1/4 Wickman

- 2 – 1 3/4 Wickman

- 3 – 1″ Wickman

- 2 – 5/8 Wickman

- 3 – 7/16 Acmes

Centerless Grinders

- Thru feed and end feed plunge grind. Tolerance will hold .0002 with 8 micro finish

- 2 – #2 Cincinnati – .040 to 3/12 diameter

- 4 – Supertec

Polishing

- 2 – standard electric 16″ machines

- Materials – aluminum, brass, stainless steel; steel to a mirror finish

Honing

- Sunnen – .125 to 2″ capacity, hold .0005 tolerance with a 16 micro finish

CNC Milling

- 1 – Akira Seiki V3, 15″x36″ table

- 1 – Fadal VMC-15, 15″x24″ table

- 1 – Leadwell MCV-OP 3rd axis, 14″x24″ table

- 1 – Shizuoka B-5V, 13″x32″ table

- 11 – Dyna Mini Mill, 4″x6″ table

- Holds .001 tolerance

CNC Turning

- 1 – Akira Seiki ASL28

- 1 – Akira Seiki ASL35

- Thru spindle to 1 3/4 diam.

- Chucking to 6″ diam.

- Hold .0005 tolerance

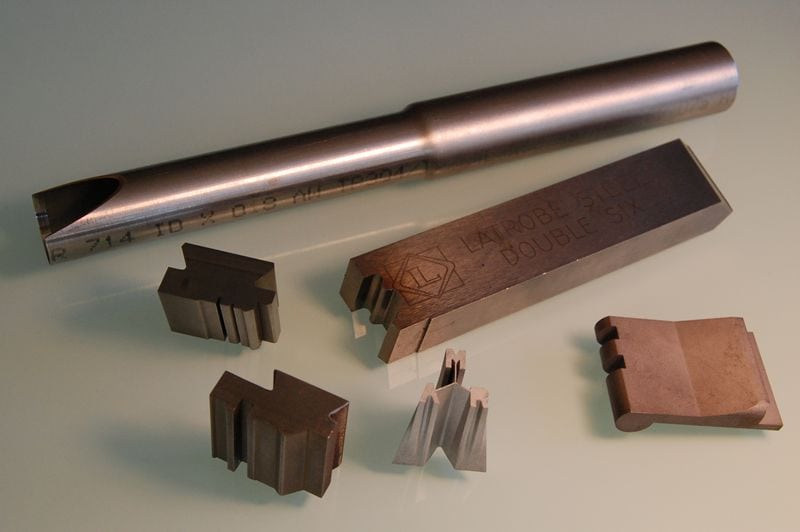

EDM

- Mitsubishi FX10

- 12″x12″x6″ Table

- All conductive materials. Specialize on high speed tools and carbide to a 16 micro finish.

Metal Finishing

- Anodize

- Chrome

- Hard Chrome

- Zinc

- Black Oxide

- Nickel

- Gold

- Teflon

- Alodine

- Powder Coat

- Passivation

- Tumble Deburring and Polishing

- For steel, alum, brass

2nd op – Lathes and Mills

- 2 – Hardinge tool room lathes

- 6 – Hardinge turret lathes

- 7 – Hardinge bradmatics

- 4 – Cincinnati Rise and Fall mills

- 1 – Nicholes twin mill

- 6 – Bridgeport mills

- 3 – Dumore Automatic drills

- 1 – Burgmaster turret drill

- 5 – Powermate tapping machines

- 5 – Micro servo drills

- Misc drills, sanders, micro sandblasting