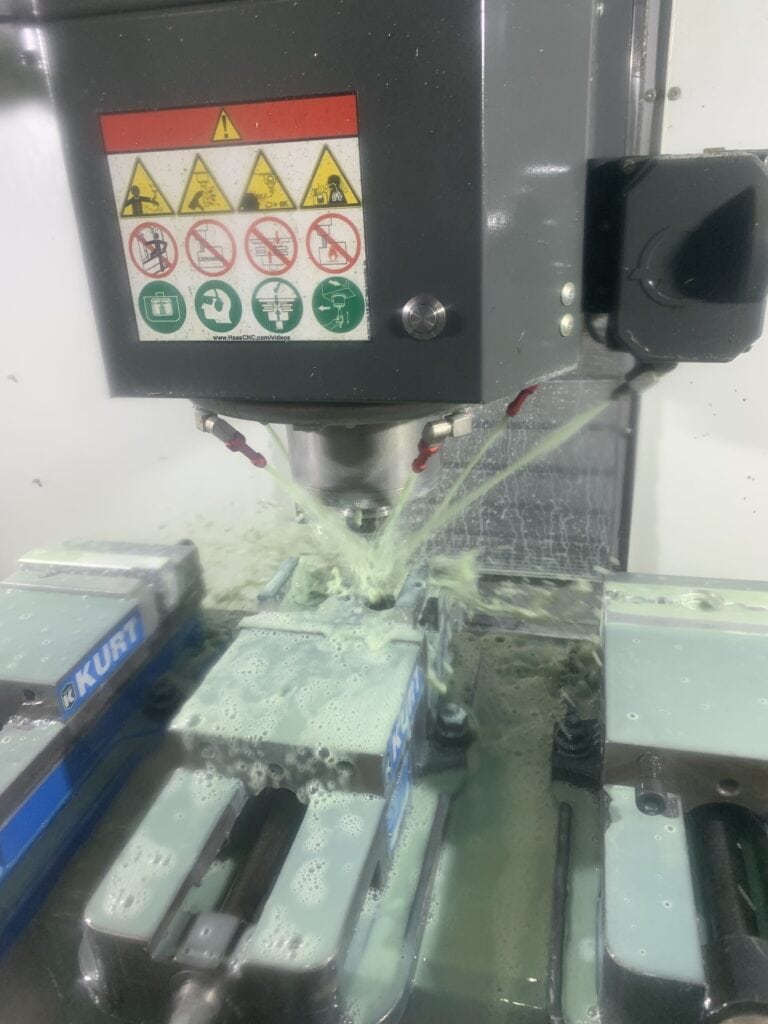

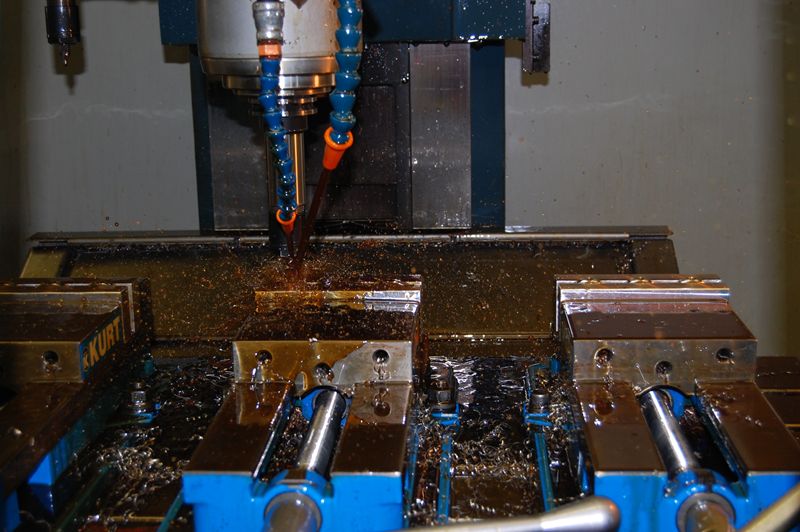

CNC Milling & Water Jetting

At M.A.R.’s Engineering we offer both CNC milling & Water jetting in house. Though used most to perform second operations on parts produced on our screw machines and CNC lathes, we also provide with a wide range of high-quality, custom-machined milled components. Whether it’s in the aerospace, automotive, or any other industry, our expertise in CNC milling and water jetting ensures unparalleled precision and cost efficiency in the production of critical parts and prototypes. By Water jetting out machining blanks and finishing the parts on the CNC Mill all in one shop, we cut down on the use of middle man and avoid extra administrative and mark up costs. We also offer 4-axis Milling.

We utilize this added capability in two different ways. The first is with the us of part indexers, this allows us rotate individual parts 360 degrees which cuts down on the need for multiple set-ups. The second is with the use of table indexers. The use of table indexers allows us to load tombstones in our mill, which allows us to fixture more parts into the machine. This cut downs on loading time greatly decreasing the time it take to produce medium and large quantity orders.

Equipment Specifications

| 3- Haas VF2/VF2SS with part indexer |

|

| 2- Haas VF2/VF0 with table indexer |

|

| 1- Akira Seiki Performa V3 with part Indexer |

|

| 2- Haas VF2/VF2SS |

|

| 1- Haas OM2A |

|

| 1- Flow Maxiem |

|