Single Spindle Screw Machining

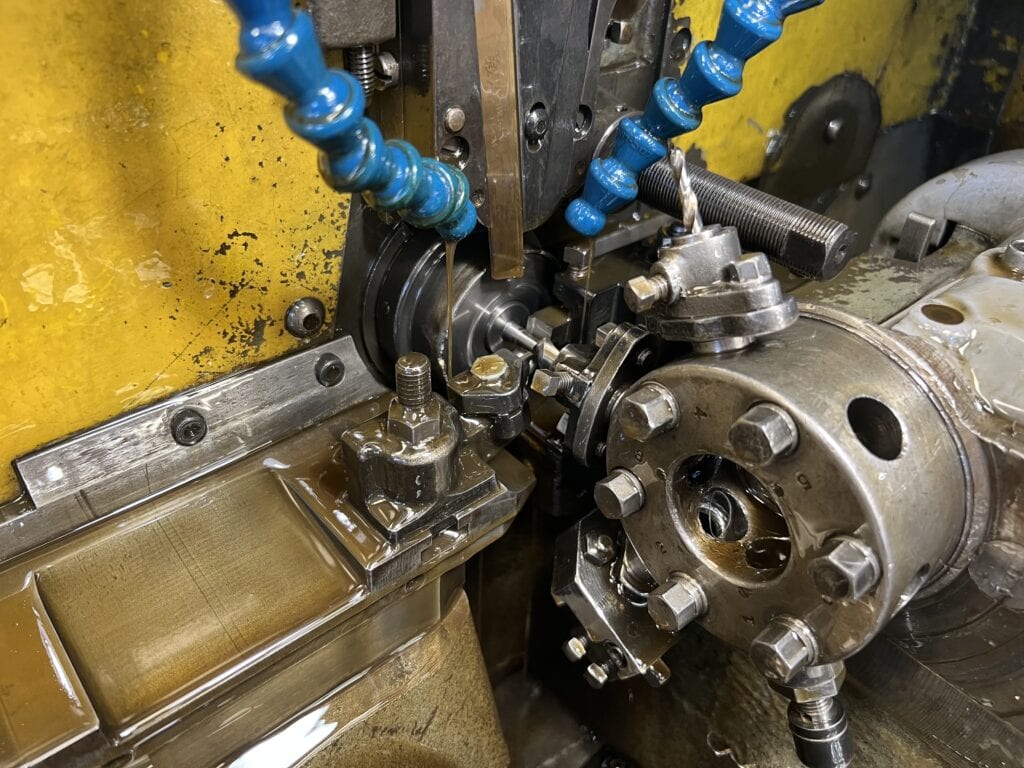

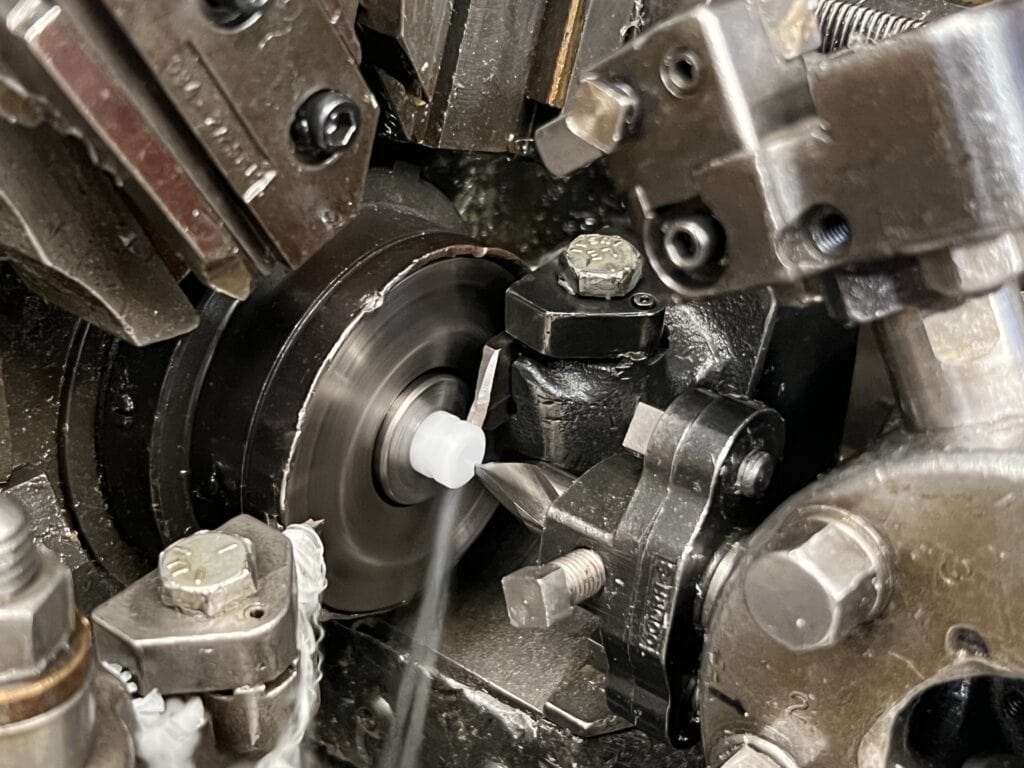

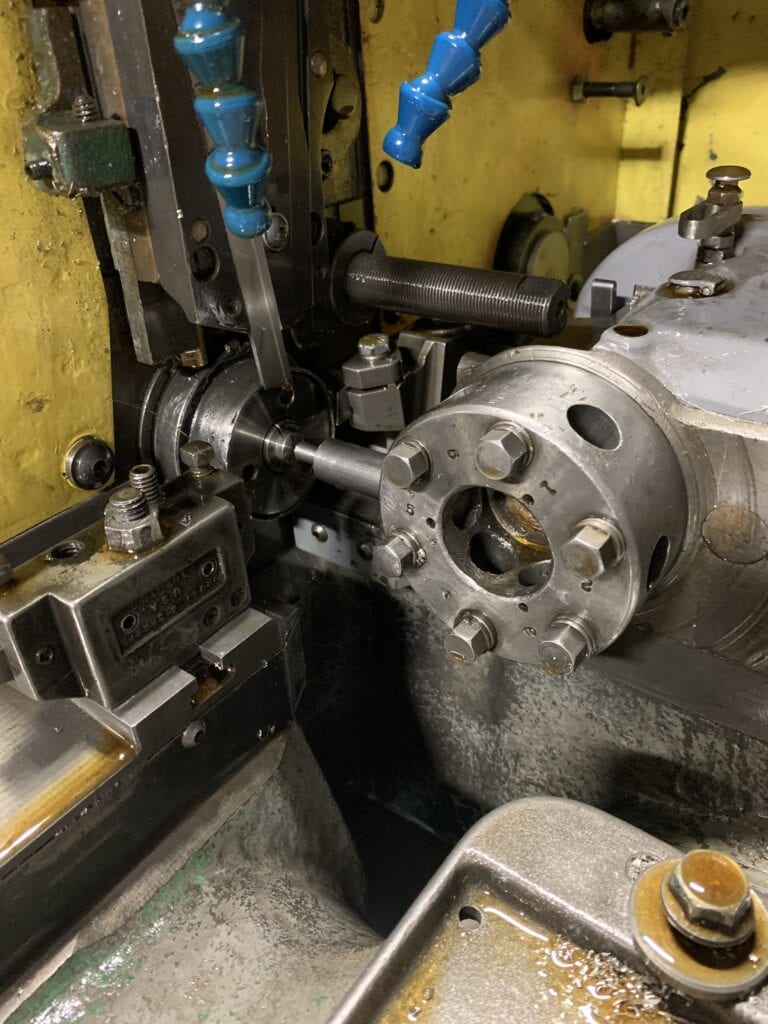

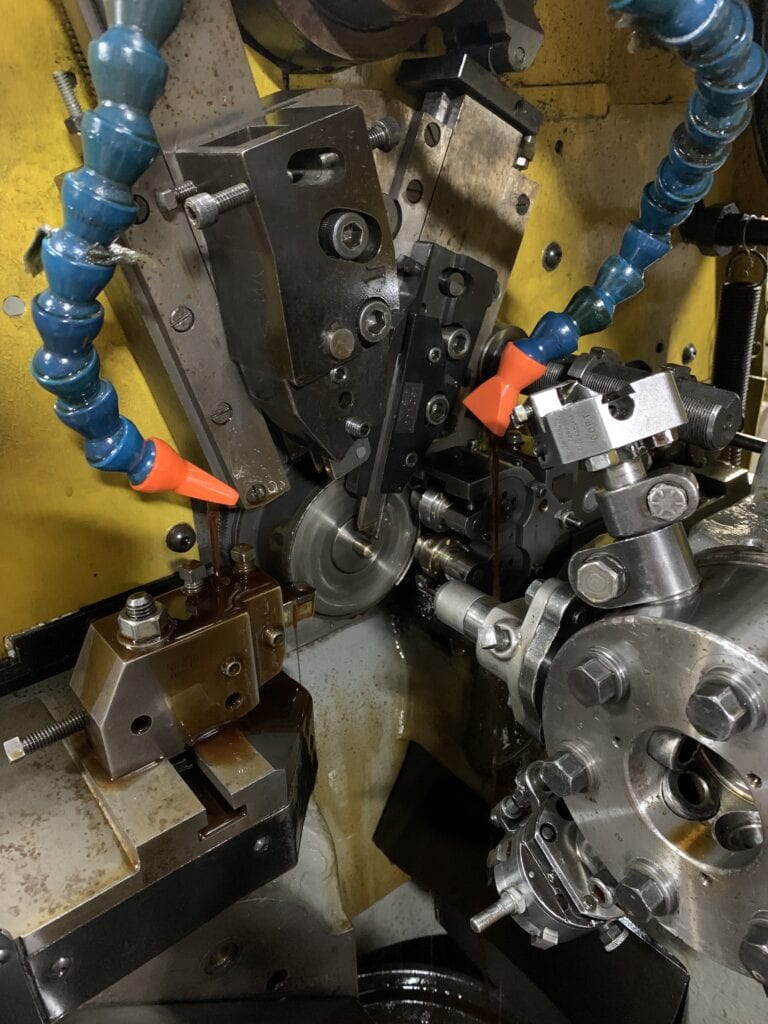

We primarily use our single-spindle screw machines for medium production runs, typically between 400 pcs and 3,000 pcs (depending on the part), with the high-volume capabilities to efficiently handle orders starting at 500+ units. There a several advantages to our single spindle screw machining over typical CNC Lathes. The first is that they are capable of having 3 tools cutting at one time, while holding a tolerance of .001 (one thousandth) of an inch. The second major advantage that single spindle screw machines have is how closely tooling rest next to its working position, which cuts down on tooling positioning time.

As a result of these two combine advantages, single spindle screw machine are able to produce parts at 2-3 times the speed of a conventional CNC lathe. Our machines are also equipped with cross drilling and milling, which cuts down on the time spent in second operation/completing the part, making these machines ideal for both medium runs and high-volume orders of 500+ units where speed and precision are equally important.

What is Single Spindle Screw Machining?

Single-spindle screw machining is a precision manufacturing process that uses a single rotating spindle to produce high-quality turned parts from bar stock. The single-spindle design allows for tight tolerances, complex geometries, and higher production, making it ideal for short to medium production runs and highly customized components. As a subset of screw machining, it emphasizes accuracy and versatility over maximum throughput.

Single vs. Multi-Spindle Screw Machining

The primary difference between single-spindle and multi-spindle screw machining is the number of workpieces produced at once. A single-spindle machine manufactures one part per cycle but is faster to set up. Multi-spindle machines, by contrast, work on several parts simultaneously, offering higher volume output but take much longer to set up. Single-spindle machining is often the better choice when ordering parts in quantities of 500-3000pcs, while Multi-spindles are ideal for quantities of 3000+ pcs.

Single-Spindle vs. Swiss Screw Machining

Both single-spindle and Swiss screw machining are trusted methods for producing precision-turned parts, but they’re designed with different goals in mind.

Single-spindle screw machining keeps the part securely positioned while multiple cutting operations are performed. This approach offers greater versatility in part sizes, higher production rate, and more efficient setups for short to mid-range production runs. It’s well-suited for components that require complexity without the expense of a Swiss setup.

Swiss screw machining uses a sliding headstock and guide bushing to support the bar stock close to the cutting area. While this is useful for very small, slender, or ultra-long parts, it typically comes with higher setup complexity and costs, making it best for extremely tight tolerance components.

When precision, adaptability, and cost-effective production of a wide variety of parts are the priority, single-spindle screw machining provides the ideal balance of quality, flexibility, and turnaround time.

Benefits of Single Spindle Screw Machining

- Precision – Capable of holding tight tolerances.

- Higher Production – often have two tools cutting at once.

- Medium Setup Time – Faster turnaround for small to mid-sized runs.

- Complex Geometry Capability – Handles intricate designs more easily than other setups.

- High Throughput – Efficiently produces 500–2,000 parts per day(depending on part) while maintaining quality.

- High Versatility – Accommodates a broad range of materials, sizes, and part complexities without costly changeovers.

Single Spindle Screw Machining FAQs

What is Screw Machining?

Screw machining is a manufacturing process that uses automated lathes to produce turned parts with high precision from bar stock. Despite the name, it’s not limited to screws; it can create a wide range of components for industries like aerospace, medical, and automotive.

When is Single Spindle Screw Machining the Best Choice?

Single spindle screw machining is best for lower to medium volumes, parts with complex features, or applications that demand frequent setup changes. Small volume production (500-2000) is a single-spindle specialty as well.

What Materials Can be Used in Single-Spindle Screw Machining?

A variety of metals and plastics can be used, including brass, aluminum, stainless steel, titanium, and engineering-grade polymers; almost any material that isn’t wood or glass can be machined.

Industries Served

Music

Automotive

Chip Manufacturing

Food Processing

Heating and Cooling

Transportation

Electrical/

Utilities

Medical

Since we opened in 1964 we have and continue to serve a wide variety of industries. In that time we have worked with a wide variety of materials and have faced a wide variety of machining challenges. Let our almost 60 years of problem solving work for you!

Equipment List

| 2- 2-1/4" #3 Brown & Sharpe Ultramatic |

|

| 5- 1-5/8" #2 Brown & Sharpe Ultramatic |

|

| 3- 1-1/4" #2 Brown & Sharpe Ultramatic |

|

| 3- 3/4" #2 Brown & Sharpe Ultramatic |

|

| 5- 3/4" 00 Brown & Sharpe Ultramatic |

|

| 13- 1/2" 00 Brown & Sharpe Ultramatic |

|