Multi-Spindle Screw Machining

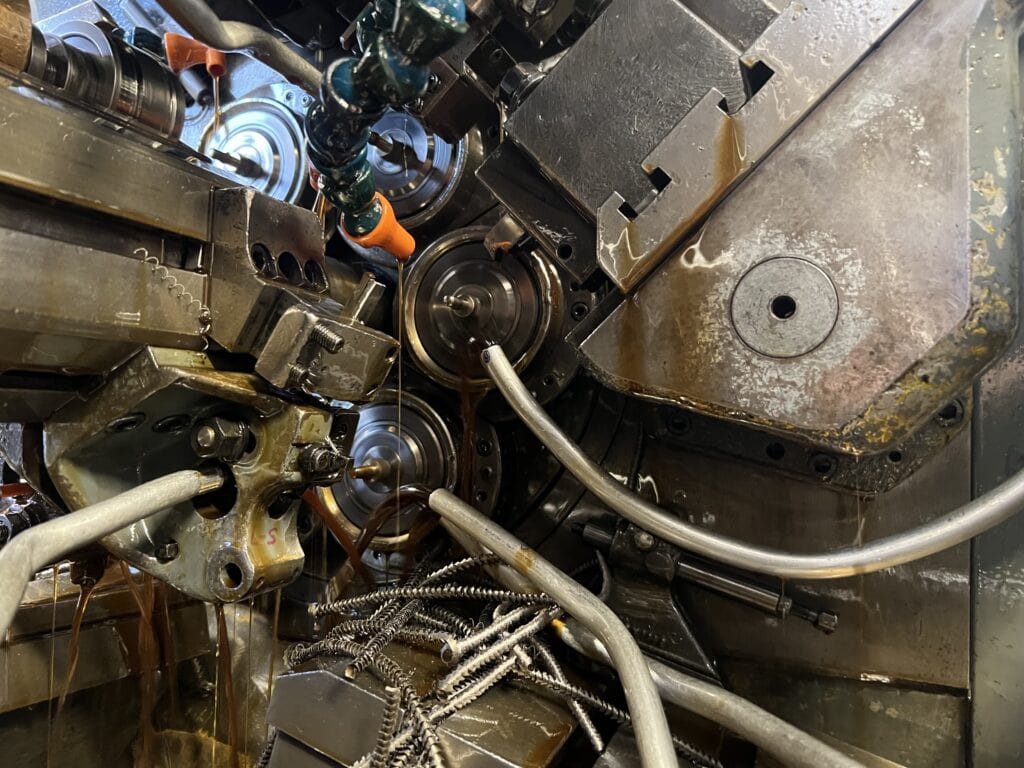

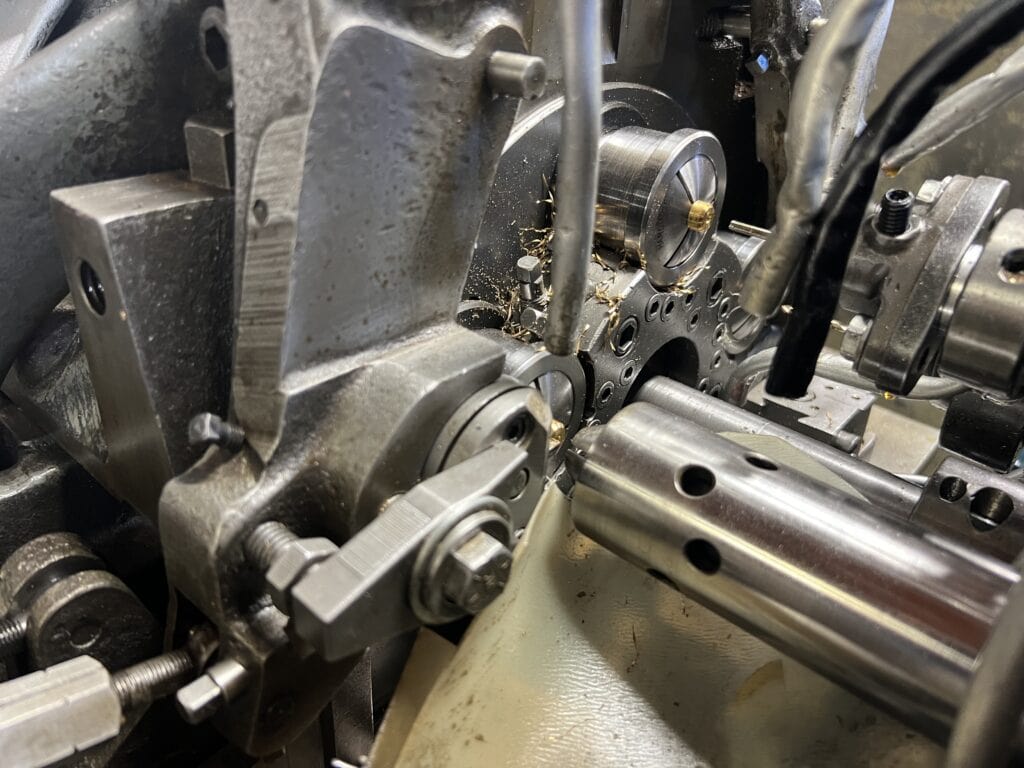

Multi-spindle screw machining offers several advantages in the realm of manufacturing. Firstly, its high-speed operation enables rapid production rates, making it exceptionally efficient for large-volume production runs of 500+ units and beyond. This increased throughput translates to lower per-part costs, making it cost-effective for high-volume manufacturing scenarios. Additionally, multi-spindle screw machines are known for their versatility, capable of handling a wide range of materials. Moreover, these machines can perform multiple operations simultaneously, such as drilling, tapping, and threading, reducing overall cycle times and improving productivity. Unlike conventional CNC lathes, the multi-spindle machines up to 16 operations at one time, all while holding a tolerance of .001 (one thousandth) of an inch.

Furthermore, the precision and consistency achieved with multi-spindle screw machining ensure high-quality finished parts, meeting tight tolerance requirements consistently. Overall, the combination of speed, versatility, and precision makes multi-spindle screw machining a preferred choice for industries requiring efficient and cost-effective mass production of precision components, with the high-volume capabilities to fulfill orders of 500+ units quickly and consistently.

What is Multi-Spindle Screw Machining?

Multi-spindle screw machining is a high-volume manufacturing process that uses multiple spindles operating simultaneously to produce several parts during each machine cycle. Each part can undergo up to 16 operations in a single setup, with the longest operation determining the overall cycle time. This means you effectively get “16 operations for the price of one,” dramatically improving throughput and cost-efficiency. This approach makes multi-spindle machining ideal for large production runs of precision-turned parts, where speed and accuracy must work together, especially for complex geometries, where more intricate parts benefit most from this all-in-one, high-volume capability.

Multi vs. Single-Spindle Screw Machining

While single-spindle machines produce one part at a time, multi-spindle machines use multiple spindles (often 5–8) to work on several parts in parallel. This significantly boosts output and reduces unit costs for large orders.

However, multi-spindle systems are typically less flexible when it comes to rapid design changes. Multi-spindle machining excels when consistency, speed, and volume are the top priorities

Benefits of Multi-Spindle Screw Machining

- High Production Speed – Multiple spindles drastically cut cycle times.

- Cost Efficiency for Large Runs – Lower per-part costs at scale.

- Consistent Quality – Uniform output across high-volume orders.

- Reduced Running Times – Faster delivery for bulk manufacturing needs.

FAQs

What is Screw Machining?

Screw machining is a process where automated lathes manufacture high-precision parts from bar stock, often used in industries like electronics, defense, and medical devices. It’s not limited to screws, either; it’s about precision turning in general.

When Should I Choose Multi-Spindle Screw Machining?

Multi-spindle machining is ideal for high-volume production runs where speed, efficiency, and consistent quality are more important than frequent design changes.

How Many Parts Can a Multi-Spindle Machine Produce at Once?

Depending on the machine configuration, multi-spindle setups can produce between 5 and 8 parts simultaneously, dramatically increasing output.

Industries Served

Music

Automotive

Chip Manufacturing

Food Processing

Heating and Cooling

Transportation

Electrical/

Utilities

Medical

Since we opened in 1964 we have and continue to serve a wide variety of industries. In that time we have worked with a wide variety of materials and have faced a wide variety of machining challenges. Let our almost 60 years of problem solving work for you!

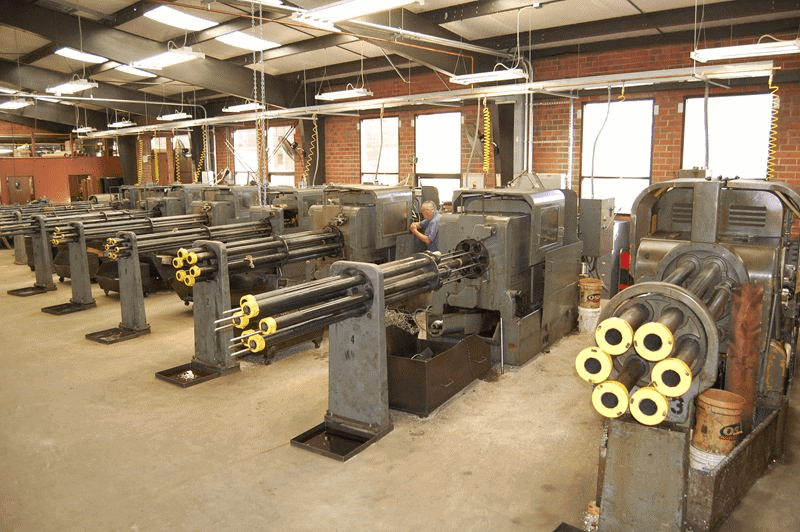

Equipment Specifications

| 1- 3-1/4" Wickman |

|

| 1- 1-3/4" 8 spindle Wickman |

|

| 2- 1-3/4" Wickman |

|

| 1- 1" 8 spindle Wickman |

|

| 3- 1" Wickman |

|

| 3- 5/8" Wickman |

|

| 1- 7/16" Acme Gridley |

|

| 10- 7/8" Davenport |

|