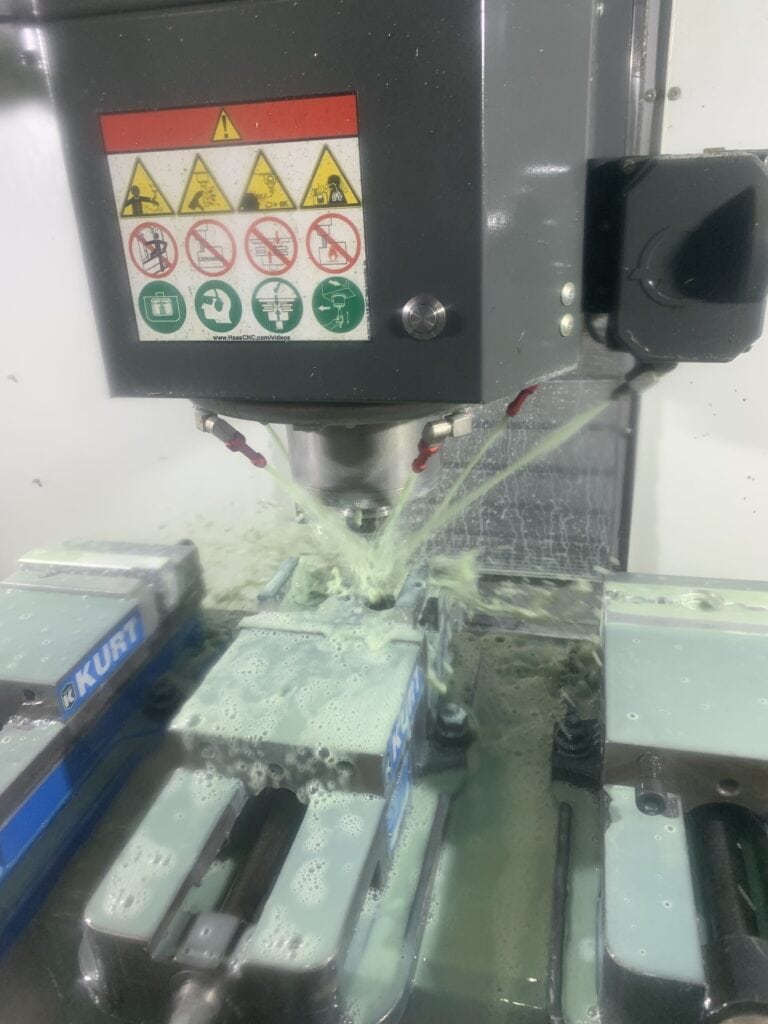

CNC Water Jetting

At M.A.R.’s Engineering, our CNC water jetting services provide precise, clean cutting of a wide variety of materials, from metals to composites, without introducing heat-related distortion. Often used to produce machining blanks for our CNC milling operations, water jetting is also ideal for producing finished parts and prototypes for industries such as aerospace, automotive, and industrial equipment manufacturing. By performing water jet cutting and any necessary finishing operations in-house, we streamline production, eliminate middleman costs, and ensure consistent quality from start to finish.

Our CNC water jetting process excels in both versatility and efficiency. We can cut complex shapes directly from sheet or plate material with exceptional edge quality, reducing or eliminating the need for secondary finishing. Water jetting is particularly valuable for thicker materials or applications where maintaining material properties is critical. By integrating water jetting into our workflow, we reduce lead times, maintain tight tolerances, and provide cost-effective solutions for both small-batch and high-volume production needs.

Equipment Specifications

| 3- Haas VF2/VF2SS with part indexer |

|

| 2- Haas VF2/VF0 with table indexer |

|

| 1- Akira Seiki Performa V3 with part Indexer |

|

| 2- Haas VF2/VF2SS |

|

| 1- Haas OM2A |

|

| 1- Flow Maxiem |

|