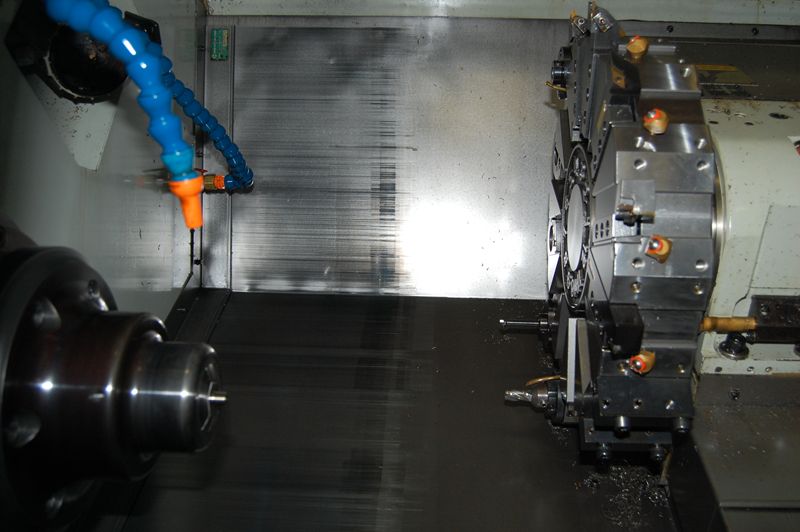

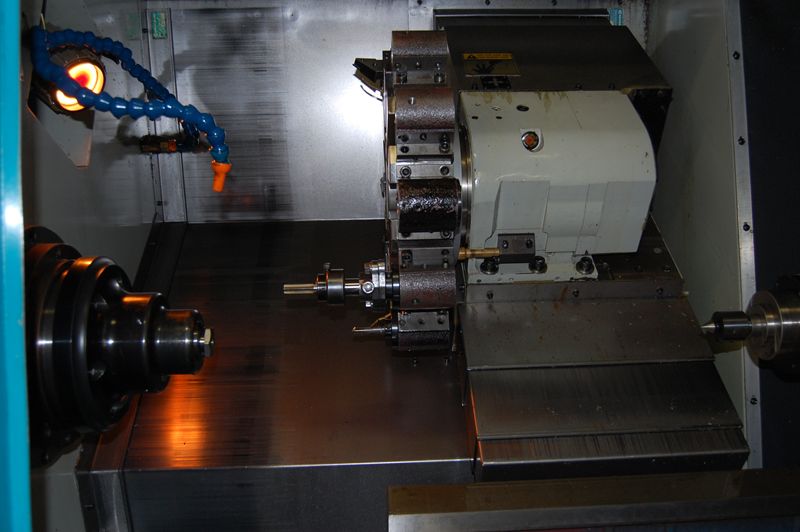

CNC Turning

At M.A.R.’s we also offer CNC turning and lathe work. There are several different way in which we leverage the ease of us of CNC lathe. The first is for smaller quantity orders. Because they are much quicker and easier to set-up than a screw machine, we often use CNC lathes for smaller quantity job cutting down on set-up costs and allowing us to maintain competitive pricing on even prototyping work, while still having the high-volume capabilities to efficiently produce runs of 500+ units when needed..

Another reason we would use a CNC lathe over a automatic screw machine is on precision work than would not be practical on our screw machines(+/-.00025). Though a screw machine could hold the tolerance, CNC lathes are easier to adjust and maintain, because tightener tolerance work requires more adjustment and tooling maintenance it often makes more since to run the part on a CNC machine.

The last major way we use our CNC lathes is using them in tandom with our automatic screw machines, producing the majority of part on the screw machines and finishing the tight tolerances that would be difficult to hold on the screw machines in the CNC machines. Though it may use two different machines, when we use the two machines together our customers get the advantage of the speed of production with the screw machine and the precision of the CNC lathes, making it possible to deliver both small prototype batches and high-volume orders of 500+ units with consistent quality.

Industries Served

Music

Automotive

Chip Manufacturing

Food Processing

Heating and Cooling

Transportation

Electrical/

Utilities

Medical

Since we opened in 1964 we have and continue to serve a wide variety of industries. In that time we have worked with a wide variety of materials and have faced a wide variety of machining challenges. Let our almost 60 years of problem solving work for you!

Equipment Specifications

| 1- Ganish Cyclone-32CS |

|

| 1-Haas ST-20Y |

|

| 1- Akira Seiki ASL-35 |

|

| 1-Haas ST-20 |

|

| 1- Haas SL-20 |

|

| 1- Yang SL-200 |

|

| 1- Akira Seiki ASL-17 |

|

| 3- Omni Turn retrofitted Hardinge lathes |

|

| 8- Omni Turn GT-75 |

|