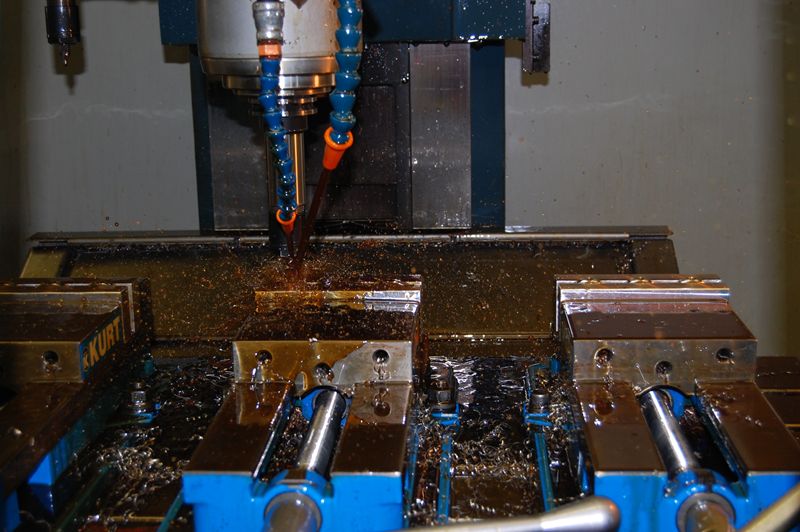

CNC Milling

At M.A.R.’s Engineering, our CNC milling services deliver high-quality, custom-machined components for industries such as aerospace, automotive, and industrial manufacturing. While we often use CNC milling to perform secondary operations on parts produced by our screw machines and CNC lathes, we also excel in producing complex parts and prototypes directly from raw material. With our in-house capabilities, we eliminate the need for outside vendors, reducing lead times, minimizing administrative overhead, and avoiding unnecessary markups. We also offer advanced 4-axis milling for intricate designs and improved efficiency.

We leverage our CNC milling equipment in two primary ways. First, we use part indexers to rotate individual parts a full 360 degrees, allowing for multiple operations without removing the part from the machine, reducing setup time and improving accuracy. Second, we use table indexers to mount tombstones, enabling us to fixture multiple parts in a single setup. This dramatically reduces loading time and increases throughput, making our CNC milling process ideal for both prototype quantities and medium-to-large production runs.

Equipment Specifications

| 3- Haas VF2/VF2SS with part indexer |

|

| 2- Haas VF2/VF0 with table indexer |

|

| 1- Akira Seiki Performa V3 with part Indexer |

|

| 2- Haas VF2/VF2SS |

|

| 1- Haas OM2A |

|

| 1- Flow Maxiem |

|